Rapid-X Inspection Services - Continuous Lengths

TCP

Inspection

Rapid-X technology enables the continuous inspection of Carbon and Glass reinforced Thermoplastic Composite Pipe (TCP), down to 50-micron sensitivity level.

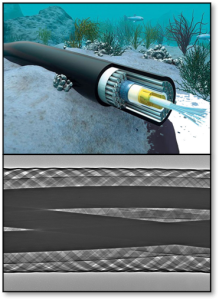

Flexible Riser

Inspection

Advanced continuous inspection of Unbonded Flexible Pipe, allows for 100% inspection of the structure, including, all tensile armours, pressure armour, carcass and insulation.

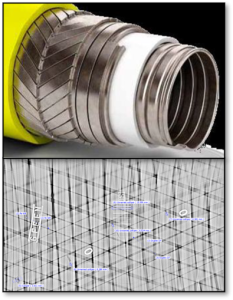

Hydrogen Pipe & Tank Inspections

DXE specialise in advanced inspections, specifically on foil lined composite materials designed for hydrogen and cryogenic systems. Down to 6-micron sensitivity.

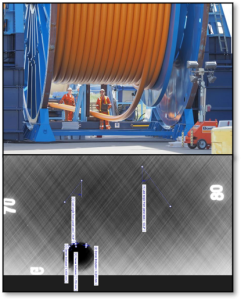

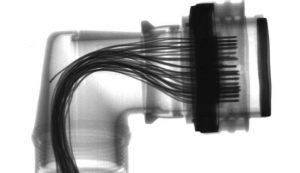

Cables & Umbilical Inspections

Cables for Off-shore Renewables Wind infrastructures are critical assets. De-Risking cables and umbilicals via inspection, avoids catastrophic failures and unplanned down time.

Inspection Solutions & Services

NDT Service

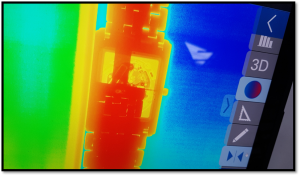

DXE Inspection Services can provide certified inspection services in any working environment. We can inspect your components at our facility or directly on site, in-situ.

Products

DXE is an official supplier of Digital Radiography equipment. We also supply a range of other NDT and inspection equipment, such as Ultrasonics, MPI & Dye-Pen

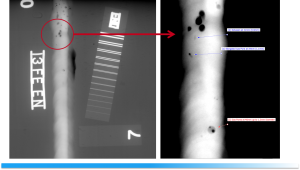

Case Studies

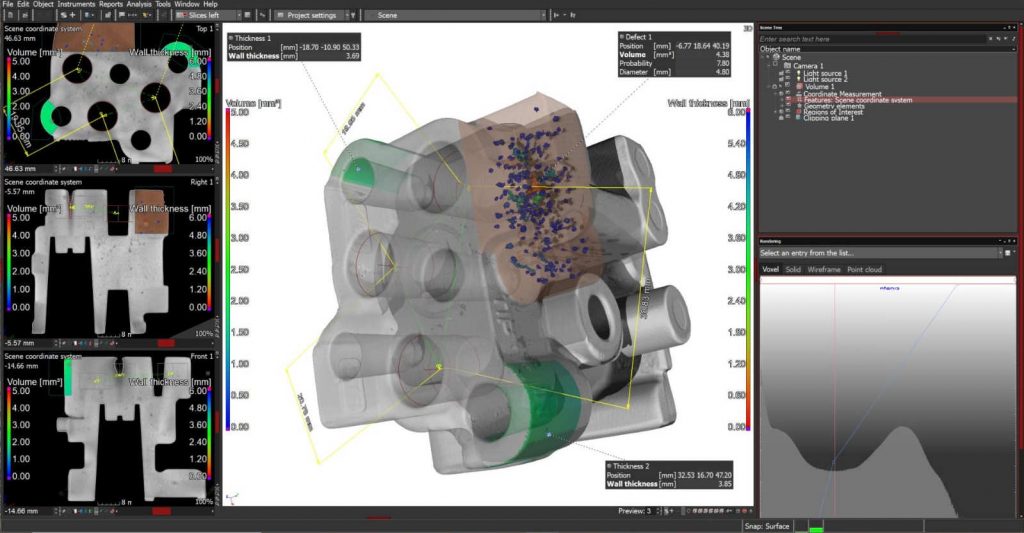

DXE have conducted various advanced case studies in demonstrating the full capability, sensitivities, coverage and possibility of detection on unique components by use of Digital RT.

A.I and Data Management

DXE develops Artificial Intelligence Models for clients to allow for instant data assessment of acquired data generated by the Rapid-X system that can inspect at 3m/min.

Client Base

On-Site Inspection Service

DXE has the unique ability to conduct advanced Digital Radiography at any worksite, including off-shore. With our fully mobile shielded inspection bay, that can be transported and installed directly onto your worksite, the mobile inspection bay can be operational within 24-hours of delivery.

Computed Tomography

Computed Tomography (CT) is an advanced non-destructive inspection technique that utilises multiple X-Ray images, each acquired in a different position to produce a full 3D model of the part/component being inspected. The end result is a spectacular high resolution slice by slice walk through the full component.

Sectors

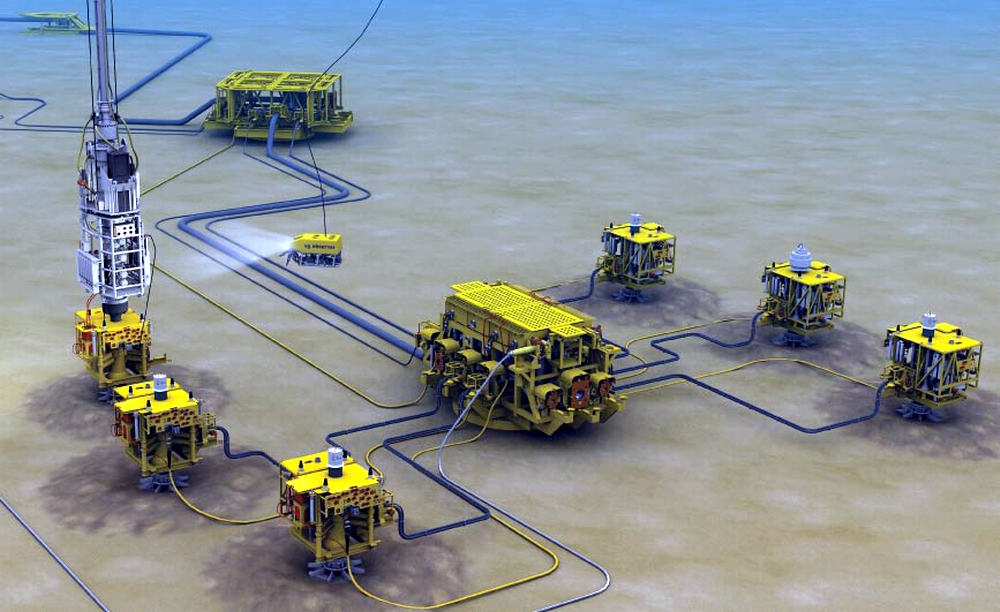

OIL & GAS

Providing advanced Non-destructive and Non Invasive inspections solutions to maintain production & reduce down.

Subsea

Materials operating in harsh subsea environments can not always be removed for inspection, so in-situe inspections are required by Divers & ROV

Automotive

Solutions for Critical composite and alloy components under extreme loads where sensitivity & turn around is extremely important.

AEROSPACE

Proving world class qualified inspection solutions to the Air & Space market, in order to maintain the integrity of each critical component.

Sites & Contact Details

DXE - UK - Head Office

Email: info@digitalxrayeng.com

Tel: (+44) 075 6462 6195

DXE - UK - Aberdeen

Email: info@digitalxrayeng.com

Tel: (+44) 075 6462 6195

DXE - Heathrow - UK

Email: info@digitalxrayeng.com

Tel: (+44) 074 1585 9739

DXE - Sheffield - UK

Email: Rex@digitalxrayeng.com

Tel: (+44) 075 6462 6195

DXE - Africa

Email: Rex@digitalxrayeng.com

Tel: (+27) 063 826 0546

DXE - Brazil

Email: brazil@digitalxrayeng.com

Tel: (+44) 075 6462 619